A new power plant that’s set to generate electricity from landfill looks set to benefit from an advanced emissions reduction system developed by a trans-Atlantic partnership led by a Derbyshire-based engineering company.

Ammegen Ltd, part of Greenbank Group UK, is set to install an advanced Selective non-catalytic reduction (SNCR) system at the UK ‘Energy From Waste’ plant.

When fully operational, the plant will deliver ‘green’ electricity to the national grid from non-recyclable Refuse Derived Fuel, with Ammegen playing a key role in maintaining low levels of NOx emissions.

Vivek Savariandam, Ammegen Division Manager explained: “SNCR system is a secondary, post-combustion process to control emissions of NOx generated by thermal power plants. It uses a urea solution to control pollutants without the need for a catalyst.

“In turn, this reduces both capital expenditure and operational costs when compared with more traditional selective catalytic reduction systems.”

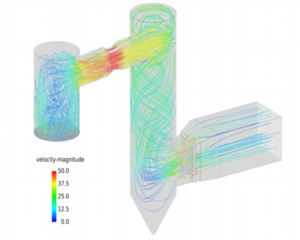

The system works by injecting diluted urea solution in the upper furnace zone where the temperature of flue gas is between 900-1100 °C. Managing the degree of dilution and the urea flow rate is dependent on mixing, residence time and temperature and critical to the performance of the system.

“The primary advantage of the Ammegen system is a metering and advanced control unit delivering optimum flow rates that maintain strict ammonia (NH3) slip rates and thereby reducing auxiliary power and associated operational costs.”

Established as a joint venture that combes the strengths of Greenbank Group (UK) and Reaction Analytic Solutions Corp. (USA), Ammegen aims to bring performance enhancement and advanced air pollution control solutions for the reduction of harmful emissions to the global power generation sector.

As part of the latest contract, Ammegen and Greenbank Terotech are set to design, supply, install and commission a SNCR system consisting of a urea storage tank, injectors, an unloading pump skid, a circulation system to prevent crystallisation and an advanced control system.

As a member of the Greenbank Group, Franklyn Yates Engineering will be installing the SNCR plant on behalf of Ammegen, in addition to installing the plant’s Air Cooled Condenser package directly for the plant’s owner/operator.

Charles Conroy, Greenbank Managing Director, added: “We’re delighted to be working on this exciting project that demonstrates the potential to deliver efficient, clean energy from landfill. The contract also demonstrates our ability to provide bespoke engineering solutions for companies at the forefront of sustainable power generation.”

As a member of the Greenbank Group, Franklyn Yates Engineering will be installing the SNCR plant on behalf of Ammegen, in addition to installing the plant’s Air Cooled Condenser package directly for the plant’s owner/operator.

Charles Conroy, Greenbank Managing Director, added: “We’re delighted to be working on this exciting project that demonstrates the potential to deliver efficient, clean energy from landfill. The contract also demonstrates our ability to provide bespoke engineering solutions for companies at the forefront of sustainable power generation.”